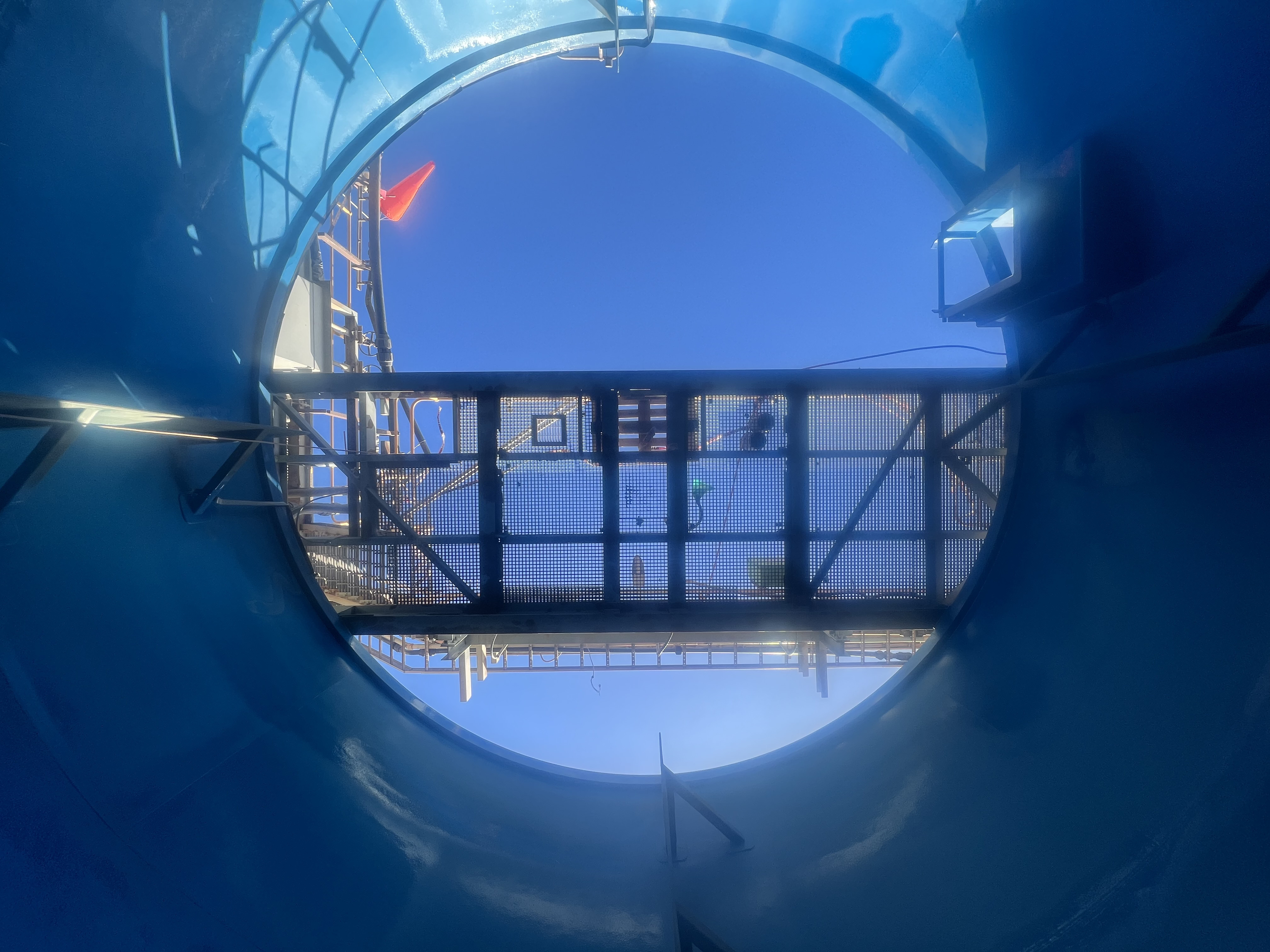

Prior to applying the coating system, Hughes Engineering focused on surface preparation to ensure optimal adhesion. This crucial step is essential for the longevity and effectiveness of the coatings on the tanks.

Surface Preparation for Optimal Adhesion

Surface preparation is a critical component of tank maintenance, directly influencing the adhesion and longevity of protective coatings. The surface should first be inspected for contaminants such as oils, greases, salts, and cargo residues, as their presence can severely compromise coating performance. A surface cleaning regimen relevant to the contaminant(s) found should be employed prior to surface preparation. For immersed steel surfaces, Hughes Engineering adheres to rigorous standards, typically preparing the carbon steel surface by abrasive blast cleaning to AS1627.4 to achieve a minimum surface appearance of Class 2.5 per ISO 8501-1, with Class 3 surface appearance target being used for more demanding applications.

During the surface preparation process not only is the required surface appearance evaluated but the prepared surface is also evaluated for a uniform angular anchor profile—both in profile depth range and profile density—which significantly increases the surface area which can be “wetted out” by a coating and promotes optimal coating adhesion. Following blasting, all residual dust is thoroughly removed via brushing or vacuum cleaning. This comprehensive level of surface cleanliness and surface preparation ensures a clean, profiled surface ready for high-performance coating application.

Why Coating Selection Matters

In demanding industrial environments, selecting the right protective coating is crucial to ensuring long-term performance and reliability. Whether it's exposure to select chemicals, abrasive materials, or corrosive conditions, the need for a robust solution is paramount.

To ensure durability, Dulux® Flexituff® DM-8 was applied @ 2000 to 3000-microns (µm) DFT. Flexituff DM-8 is a two-component polyurea elastomer designed to provide good protection against abrasion and corrosion.

Dulux® Flexituff® DM-8: Superior Protection Against Abrasion and Corrosion

Flexituff DM-8 provides a seamless, impact-absorbing, tear-resistant finish suitable for industrial applications like mining, process industries, select sewage, and waste treatment plant applications. It complies with AS4020-2018 potable water applications, can be applied directly to prepared steel without a primer, and sets dry immediately upon contact for efficient and fast results. A full cure is recommended over several days to ensure better performance.

When it comes to the benefits of Flexituff DM-8, users can expect reliable protection against impact and abrasion, thanks to its thick rubbery coating. This coating solution allows time-saving application directly onto metal surfaces without the requirement of a primer, enhancing efficiency and convenience.

“What sets Flexituff DM-8 apart as a superior coating solution includes excellent abrasion resistance, fast curing time, and the ability to be applied directly onto correctly prepared steel surfaces. With a 100% solids composition and low VOC emissions, Flexituff DM-8 offers a high-performance coating option that prioritises durability and environmental considerations”, says Kyle Nesbitt from Dulux® Protective Coatings.

Image courtesy of Hughes Engineering.